The INTELI-jet required a lot of effort from different collaborative partners to be completed. We interviewed Devin Dixon from Celero Partners, a group that played a pivotal role in the design and development of the INTELI-jet. Celero Partners uses 3D designing, scanning, and printing to develop parts and products for different clients. By closely collaborating with Celero on all stages of design, we were able to create an innovative product built to fit customers’ needs.

Here’s what Devin had to say about his work at Celero and how he helped:

What work does Celero do, and how does it support the work at Arborjet | Ecologel?

Celero specializes in the design and engineering of innovative products that seamlessly blend form and function, with a particular emphasis on 3D printing and 3D scanning. This expertise aligns with the goals of Arborjet | Ecologel’s dedication to advanced solutions for plant health care. By leveraging our design and manufacturing capabilities, we support Arborjet | Ecologel in developing innovating devices.

What brought you to Celero Partners?

My journey to Celero Partners was driven by a passion for mechanical design and an interest in utilizing cutting-edge technologies like 3D printing to solve complex engineering challenges. After gaining extensive experience in additive manufacturing and product design, I was eager to find a role where I could apply my skills in an innovative environment. Celero stood out as a company at the forefront of engineering solutions in its field, making it an ideal place for me to contribute to groundbreaking projects in the forestry industry.

What is your background?

My background is mechanical engineering, 3D printing, and business development. My professional journey has consisted mainly of roles in research and development. Prior to joining Celero, I had the privilege to work in the UMass Amherst Advanced Digital Design and Fabrication lab, utilizing state-of-the-art machinery to 3D print with materials like stainless steel and chopped carbon fiber. Additionally, I did undergraduate research with the UMass Amherst Human Robotic Systems Laboratory where I applied my knowledge of 3D printing to develop and test complex lattice structures.

When did Celero Partners become involved with developing the INTELI-jet?

Celero has been working with Arborjet from the very beginning, working under the direction of CEO Russ Davis. Russ was the lead on the design, and Celero created and tested the different designs for the 3D printed shell, as well as the programing for the device.

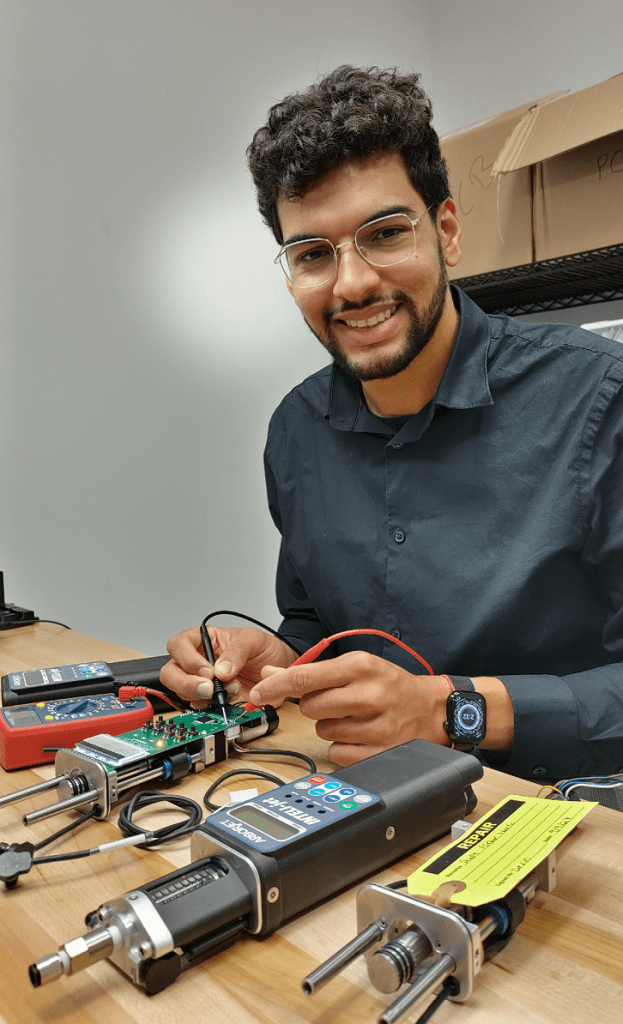

How did you use your expertise to help develop the INTELI-jet?

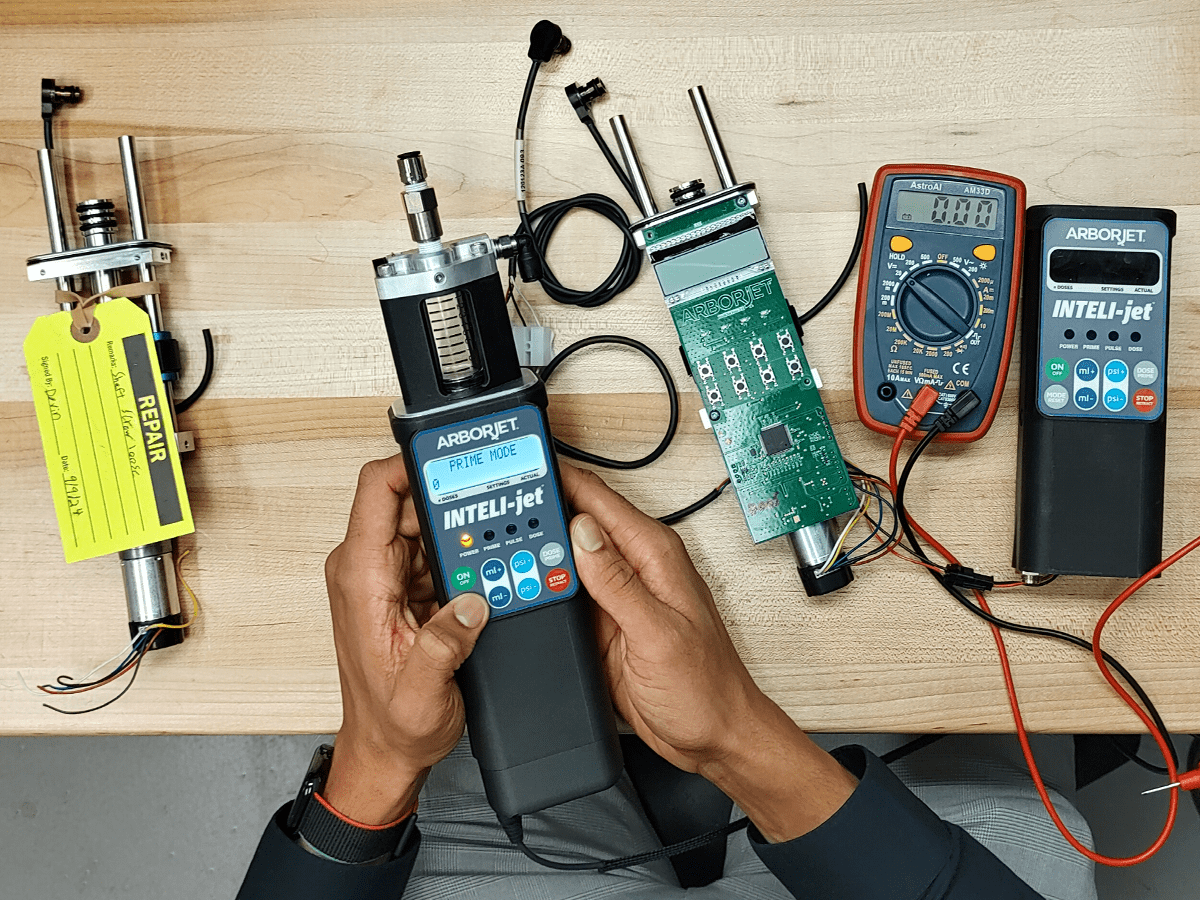

A key focus of my role involved developing the printing process for the device’s carbon fiber components. With my expertise in 3D printing technologies, I was able to optimize the design and manufacturing process for these critical components, ensuring they met our requirements for strength, durability, and performance. The INTELI-jet went through several iterations to test the design for comfort and weight, so it could be held in one hand, and through many rounds of testing to make sure it could survive the wear and tear of field work.

How did it feel to be part of bringing an innovative product or device to market?

Being part of the team that brought the INTELI-jet to market has been an incredibly experience. I am glad to have had the opportunity to work with such an amazing team and contribute to the development of this device.

Learn more about the INTELI-jet at https://arborjet.com/products/inteli-jet/